source:other news

release time:2022-11-10

Hits:0

Popular:

(1) The tests conducted by the battery manufacturer to test the quality of lithium battery pack include: capacity division test, charging test, discharge test, short circuit test, internal resistance test, voltage test, resistance test, over-current protection test, complete machine test, etc. The partial capacity test takes 0.2C, 0.5c, 1C as the standard, and carries out routine and rapid charge discharge tests respectively. It is very important to activate the lithium battery pack and judge its capacity and performance. Charging and discharging test The charging and discharging test is to judge whether the charging and discharging circuit of lithium battery works normally. This test has certain requirements for charging voltage and current. Overcurrent protection test After the lithium battery pack is fully charged, use an adjustable resistor to adjust the discharge current to gradually increase the current. When the discharge current is greater than a certain voltage value, the discharge circuit current will be disconnected and become zero. The current recorded before current disconnection is the overcurrent protection current.

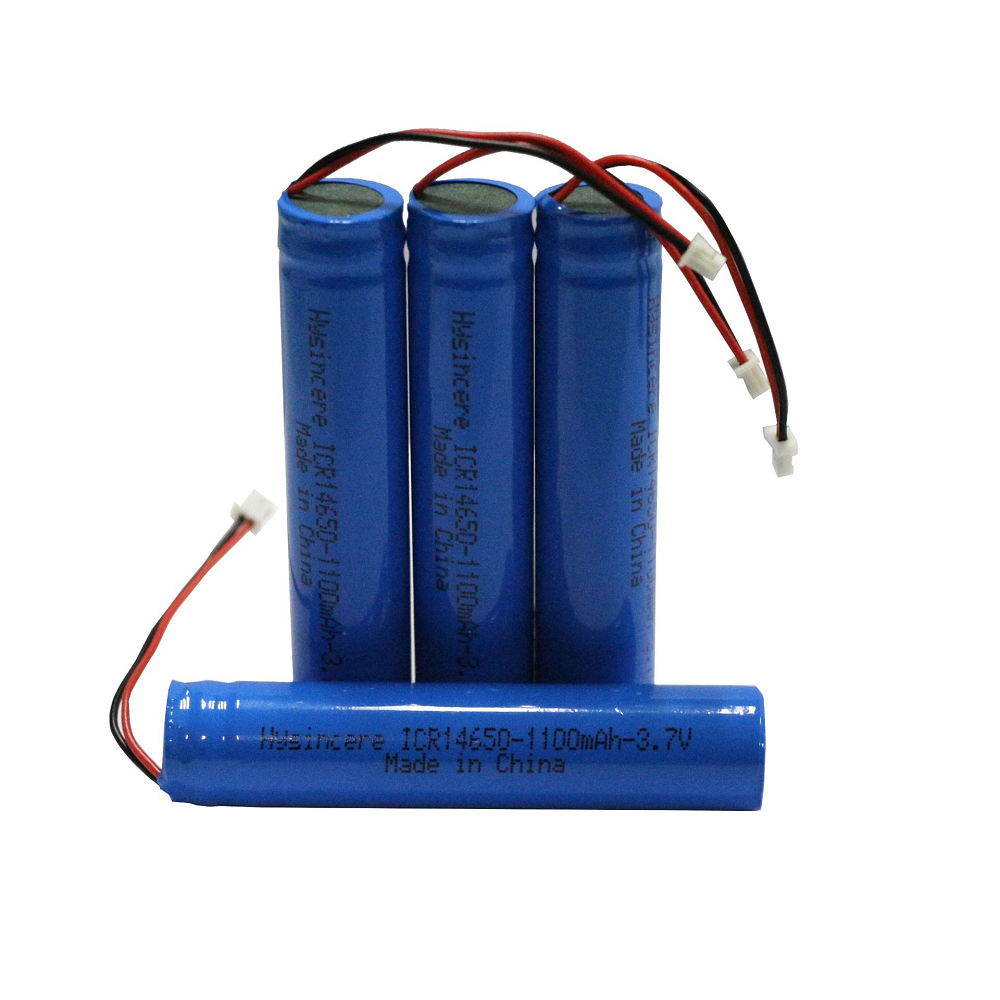

(2) Users can test the internal resistance and discharge current of the battery by testing the quality of the lithium battery. If relevant tools are available, internal resistance and maximum discharge current can be tested. The lithium battery with good quality has small internal resistance and large maximum discharge current. Use a 20A multimeter to directly short-circuit the two electrodes of the lithium battery. The current should generally be about 10A or even higher, and can be maintained for a period of time. A good lithium battery pack is relatively stable. Look at the plump appearance. For example, a lithium battery pack of about 2000mAh is relatively large. Fine workmanship or packaging looks plump.

Read recommendations:

deep cycle marine battery wholesaler

High Temperature Lithium Battery 18650 26650 Cell

Optimizing Energy Storage: Key Considerations for Businesses

Last article:Discovery and working principle of battery

Next article:What kinds of batteries can be used in electric vehicles?

related suggestion

lithium batteries for boats Factory

2023-03-20solar battery for house direct sales

2023-03-20lithium deep cycle marine battery direct sales

2023-04-07solar energy storage Factory

2023-03-20lithium deep cycle marine battery Manufacturing

2023-04-07lifepo4 solar battery Processing

2023-04-07lifepo4 12v

2023-05-08solar battery generator

2023-05-08best solar powered generator

2023-05-0812 volt deep cycle marine battery

2023-05-08portable battery generators

2023-05-0812v solar battery

2023-05-0876.8V 37.5Ah LiFePO4 Battery for Electric Motorcycles

2025-05-2112V Rechargeable Lithium Ion 18650 Battery Pack 2000mAh

2023-02-14Golf Cart 51.2V 105Ah LiFePo4 Battery Pack IP67 Waterproof with Bluetooth

2022-09-2960V 48Ah LiFePO4 Battery for Two-Wheeler E-Mobility

2025-05-29Lithium Polymer Battery Pack for Smart Home Device

2023-02-14The Power and Precision of Dual 18650 Box Mods: A Comprehensive Overview

2025-03-19The Advantages of 21700 Rechargeable Li-Ion Batteries for Industrial Applications

2025-09-30Reliable Power for Industrial Applications: Understanding the 2200mAh 18650 Battery

2025-10-11Power lithium battery is the "foundation" of the future of new energy cars.solar generator for camping

2023-06-05Energy Storage Market in Asia-Pacific: Key Players, Innovations, and Industry Insights

2025-03-13Lithium power battery characteristics advantages.solar generator for home

2023-07-11Packaging and design requirements for finished lithium batteries

2023-10-11Operation status and efficiency.portable battery generators

2023-06-05What is the working principle of lithium-ion batteries?solar powered generator for home

2023-06-20How to prolong the battery life of mobile phone/computer.best trolling motor battery

2023-07-03